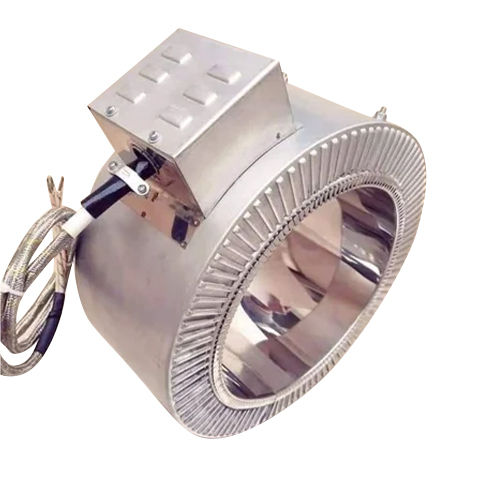

Stainless Steel Mica Band Heater

Product Details:

- Material Stainless Steel

- Voltage 240 Volt (v)

- Power Source Electric

- Color Silver

- Click to View more

Stainless Steel Mica Band Heater Price And Quantity

- 200 INR/Piece

- 100 Piece

Stainless Steel Mica Band Heater Product Specifications

- 240 Volt (v)

- Silver

- Stainless Steel

- Electric

Stainless Steel Mica Band Heater Trade Information

- Cash in Advance (CID)

- 100000 Piece Per Month

- 7 Days

- South India

Product Description

A type of electric heater called a stainless steel mica band heater is used in industrial settings to efficiently and uniformly heat cylindrical objects. These band warmers are made of mica insulation and a stainless steel sheath.

The following are some essential qualities and traits of stainless steel mica band heaters:

1. Sheath Made of Stainless Steel: The band heater's exterior sheath is constructed of stainless steel, which has outstanding corrosion resistance and durability. Applications involving exposure to moisture, chemicals, or extreme environments are ideal for stainless steel.

2. Mica Insulation: Mica, a mineral-based substance with outstanding electrical insulation qualities and high-temperature endurance, is used to insulate the heating element inside the band heater. Mica insulation distributes heat towards the intended item while assisting in preventing heat loss.

3. An even distribution of heat is provided by stainless steel mica band heaters all the way around the band. As a result, temperature fluctuations and hotspots are reduced while the cylindrical object is heated consistently and effectively.

4. High-Temperature Capability: Depending on the exact setup and application needs, these band heaters are designed to work at high temperatures, often ranging from 300 deg C to 700 deg C (572 deg F to 1292 deg F).

5. Stainless steel mica band heaters have quick heat-up and cool-down durations, enabling rapid reaction and precise temperature control. This is advantageous for procedures that call for rapid temperature changes or heating cycles.

6. Flexibility: Stainless steel mica band warmers can be made to fit a variety of cylinders, including pipes, barrels, and containers. For various application requirements, they come in various sizes, watt densities, and combinations.

7. These band heaters are used in a variety of operations that call for the reliable and efficient heating of cylindrical products, including extrusion, food processing, packaging, and the processing of polymers.

When employing stainless steel mica band heaters, it's crucial to adhere to safety regulations and good installation techniques. To guarantee optimal performance, lifespan, and safety in industrial settings, routine maintenance and inspection are advised.

Other Products in 'Band Heater' category

GST : 29AAYPJ3561B2ZF

Send Inquiry

Send Inquiry Send SMS

Send SMS