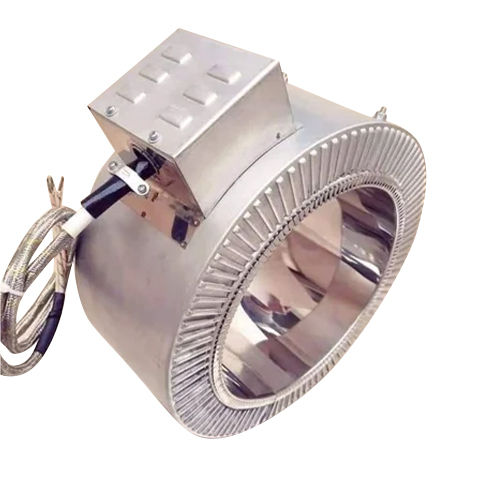

240 V Band Heater

Product Details:

- Material Stainless Steel

- Voltage 240 Volt (v)

- Power Source Electric

- Color Silver

- Click to View more

240 V Band Heater Price And Quantity

- 200 INR/Piece

- 100 Piece

240 V Band Heater Product Specifications

- Silver

- Electric

- 240 Volt (v)

- Stainless Steel

240 V Band Heater Trade Information

- Cash in Advance (CID)

- 100000 Piece Per Month

- 7 Days

- South India

Product Description

An electrical heating tool called a 240V band heater is made to wrap around cylindrical items like pipes or containers in order to give even warmth. It runs on 240 volts, which is a widely used standard voltage in many places.

Here are some essential details regarding 240V band heaters:

1. The band heater was created specifically to work at 240 volts. It's critical to confirm that the power supply and electrical system can handle this voltage.

2. Heating Element: A heating element, often formed of resistance wire, is encased in an insulating substance and used in band heaters. The heating element generates heat when it is activated, which is then transferred to the object it is wrapped around.

3. Temperature Control: To manage and maintain the appropriate temperature, band heaters frequently incorporate built-in temperature control functions. This might incorporate temperature controllers or thermostats that enable exact temperature adjustments.

4. Installation: Band warmers are made to be quickly and securely fastened around cylinders. To achieve a tight fit, they frequently contain adjustable bands or clamps that may be adjusted.

5. Applications: Band heaters are frequently employed in a range of industrial processes, including plastic processing, injection moulding, extrusion, and other procedures that call for the carefully regulated heating of cylindrical items. They help maintain stable temperature profiles by distributing heat effectively and uniformly.

6. Band heaters can be made to order to fulfil unique specifications, including size, power, and temperature range. This makes it possible to be compatible with many applications and guarantees top performance.

It is crucial to adhere to the correct safety measures and standards when using a 240V band heater or other electrical heating device. These include utilising the correct electrical connections, insulation, and temperature monitoring to avoid overheating or other risks.

Other Products in 'Band Heater' category

GST : 29AAYPJ3561B2ZF

Send Inquiry

Send Inquiry Send SMS

Send SMS