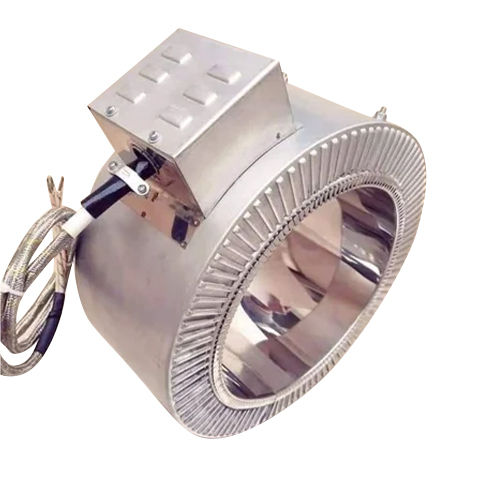

220 V Ceramic Band Heater

Product Details:

- Voltage 220 Volt (v)

- Power 8 Watt (w)

- Power Source Electric

- Color Silver

- Click to View more

220 V Ceramic Band Heater Price And Quantity

- 450 INR/Piece

- 100 Piece

220 V Ceramic Band Heater Product Specifications

- Silver

- 8 Watt (w)

- 220 Volt (v)

- Electric

220 V Ceramic Band Heater Trade Information

- Cash in Advance (CID)

- 100000 Piece Per Month

- 7 Days

- All India

Product Description

A band heater that is made for industrial applications that need high-performance heating capabilities is referred to as a heavy-duty band heater. These band warmers are designed to tolerate harsh situations, distribute heat effectively, and offer increased longevity.

The following are some significant qualities and traits of powerful band heaters:

1. Construction: To ensure durability and lifespan, heavy-duty band warmers are often built using strong materials and components. They frequently have a tough outer sheath comprised of high-temperature alloys or materials like stainless steel that can survive challenging operating conditions.

2. High Watt Density: Because heavy-duty band heaters can handle high watt densities, the target object can be heated quickly and effectively. They can produce more heat output per unit of surface area, which is advantageous in applications requiring quick heating.

3. Enhanced Insulation: To reduce heat loss and increase energy efficiency, these band heaters frequently use cutting-edge insulation materials. Effective insulation aids in preserving the correct temperature while minimising heat transfer to the surroundings.

4. Temperature Control: Robust temperature control devices, such as thermocouples and temperature controllers, can be added to heavy-duty band heaters. These characteristics make it possible to precisely monitor and control the heating process, guaranteeing top performance and avoiding overheating.

5. Secure Installation: These band warmers are made to be installed around cylindrical items in a safe and stable manner. To enhance effective heat transfer and reduce heat loss, they frequently have robust clamping mechanisms or adjustable bands that offer a tight fit.

6. Heavy-duty band heaters are used in a variety of industrial settings, such as food processing, metal processing, plastic processing, injection moulding, and extrusion. They can be used in industrial processes to heat barrels, pipes, tanks, and other cylindrical things.

7. Heavy-duty band heaters can be modified to fit certain needs, including those related to size, wattage, voltage, and temperature range. Possibilities for customization enable interoperability with various tools and procedures.

It is essential to adhere to safety precautions while utilising heavy-duty band heaters, including adequate electrical connections, insulation, and temperature monitoring to avoid overheating, equipment damage, or workplace risks.

Other Products in 'Band Heater' category

GST : 29AAYPJ3561B2ZF

Send Inquiry

Send Inquiry Send SMS

Send SMS